In the rapidly evolving landscape of energy storage, lithium-ion batteries have emerged as a cornerstone technology. Among the various chemistries available, two of the most prominent are Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC). Each has its unique set of characteristics, advantages, and limitations, making them suitable for different applications. This article aims to provide a comparative analysis of LFP and NMC batteries, shedding light on their respective strengths and weaknesses.

Chemical Composition and Structure

LFP (Lithium Iron Phosphate):

LFP batteries use lithium iron phosphate as the cathode material and typically graphite as the anode. The chemical composition is denoted as LiFePO4. The olivine structure of LFP provides excellent thermal stability and safety.

NMC (Nickel Manganese Cobalt):

NMC batteries utilize a combination of nickel, manganese, and cobalt in their cathode, with a typical composition ratio being 1:1:1 or variations like 8:1:1. The general formula is Li(NiMnCo)O2. The layered structure of NMC allows for high energy density and good overall performance.

Energy Density

One of the key differentiators between LFP and NMC batteries is energy density.

LFP (Lithium Iron Phosphate):

LFP batteries generally have a lower energy density, ranging between 90-120 Wh/kg. This makes them bulkier for the same amount of stored energy compared to NMC batteries.

NMC (Nickel Manganese Cobalt):

NMC batteries boast higher energy densities, typically around 150-220 Wh/kg. This makes them more suitable for applications where space and weight are critical factors, such as in electric vehicles (EVs).

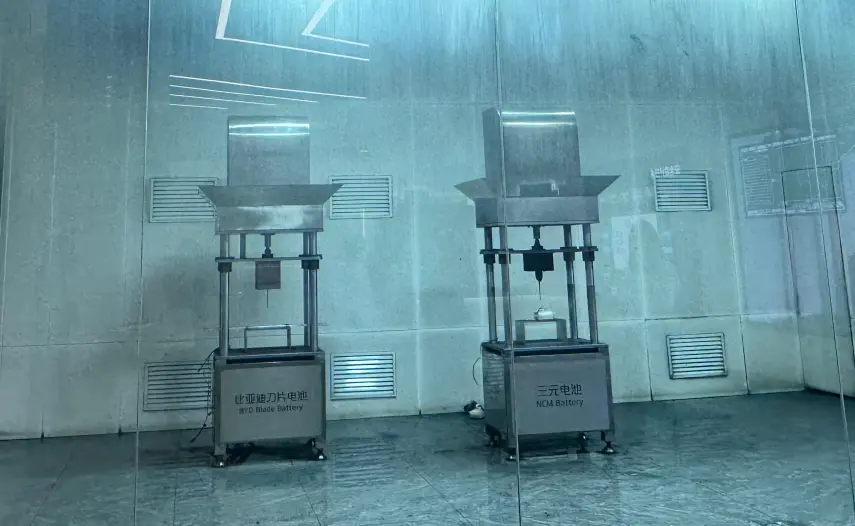

Safety and Thermal Stability

Safety is paramount when it comes to battery technologies, especially in large-scale applications.

LFP (Lithium Iron Phosphate):

LFP batteries are renowned for their superior thermal stability and safety. They are less prone to overheating and thermal runaway, making them an excellent choice for applications requiring high levels of safety, such as grid storage and residential energy systems.

NMC (Nickel Manganese Cobalt):

While NMC batteries also offer good safety features, they are more susceptible to thermal runaway compared to LFP. Advances in battery management systems (BMS) and cooling technologies have mitigated these risks to some extent, but LFP still holds the upper hand in this regard.

Cycle Life

The lifespan of a battery is a crucial factor that determines its long-term viability and cost-effectiveness.

LFP (Lithium Iron Phosphate):

LFP batteries typically offer a longer cycle life, often exceeding 2000 cycles before significant degradation occurs. This makes them ideal for applications where longevity is essential, such as stationary storage solutions.

NMC (Nickel Manganese Cobalt):

NMC batteries usually have a shorter cycle life, ranging from 1000 to 2000 cycles. However, ongoing research and development are continually improving their durability.

Cost Considerations

Cost is another critical aspect that influences the choice between LFP and NMC batteries.

LFP (Lithium Iron Phosphate):

LFP batteries generally have lower raw material costs due to the abundance and lower price of iron and phosphate. This makes them more affordable, particularly for large-scale applications.

NMC (Nickel Manganese Cobalt):

NMC batteries tend to be more expensive, primarily due to the high cost of cobalt and nickel. However, their higher energy density can offset the initial cost by reducing the number of cells needed for a given application.

Environmental Impact

Environmental considerations are becoming increasingly important in the evaluation of battery technologies.

LFP (Lithium Iron Phosphate):

LFP batteries have a lower environmental impact due to the absence of cobalt, which is often associated with ethical and environmental issues related to mining practices.

NMC (Nickel Manganese Cobalt):

The use of cobalt in NMC batteries raises concerns regarding human rights and environmental degradation. Efforts are underway to reduce the cobalt content or find alternative materials, but these challenges remain.

Applications

The distinct characteristics of LFP and NMC batteries make them suitable for different applications.

LFP (Lithium Iron Phosphate):

Given their safety, long cycle life, and lower cost, LFP batteries are commonly used in stationary energy storage systems, low-speed electric vehicles, and backup power supplies.

NMC (Nickel Manganese Cobalt):

With their higher energy density, NMC batteries are favored in high-performance applications such as electric vehicles, portable electronics, and power tools.

Both LFP and NMC batteries have their unique advantages and limitations, making them suitable for different applications. LFP batteries excel in safety, longevity, and cost-effectiveness, while NMC batteries offer higher energy density and better performance in space-constrained applications. Understanding these differences is crucial for selecting the right battery technology to meet specific needs and requirements.

As the demand for efficient and sustainable energy storage solutions continues to grow, ongoing advancements in both LFP and NMC technologies promise to further enhance their capabilities and broaden their range of applications.